Reasons for resin yellowing after some time.

What is the reason for yellowing resin products after a while؟

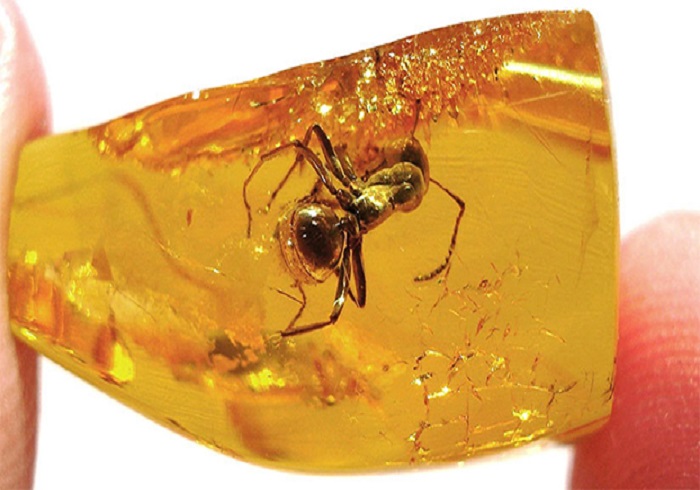

One of the main problems of working with epoxy resin is the yellowing of epoxy resin. Yellowing of epoxy resin or hardener sometimes occurs in their own glass and sometimes turns yellow after drying and passing the baking stage.

In addition to the fact that your epoxy resin can change color, you may notice that your epoxy hardener agent also turns yellow and discolors in the bottle you hold in. (Hardner Yellow)

However, this is not caused by ultraviolet light, but by the oxidation of compounds in the bottle itself. When you open the new Hardner Epoxy bottle and let the air into the bottle, you start the process and there is no way to slow it down.

Not all epoxy shapes turn yellow and it is possible to purchase epoxy resin with a special formula that does not change color, but most forms change color and there are three main reasons for this.

Epoxy aging:

If your epoxy resin becomes old and a year has passed since it was made, the possibility of yellowing the epoxy resin is high.

Oxidation of epoxy resin:

If the epoxy resin or hardener is exposed to oxygen or open air, they oxidize and the epoxy resin turns yellow.

Epoxy yellowing with closed door:

In some cases, you may see that the hardener or epoxy is still yellow in color without exposure to the open air and despite the fact that its door is closed،The reason for this phenomenon or HDPE plastic doors (these doors with tiny holes)

are associated) or keeping the resin in a space with high temperature fluctuations.

What is the cause of yellowing of epoxy resin after drying؟

If after a few months, you see the color change of epoxy resin towards yellowing ، The main reason is the weakness of epoxy against UV light, which after some time causes the surface of the epoxy to turn yellow.

It is good to know that if you put the resin product in front of the light and move it to a better place after a short period of time, there will be no change and the resin product will definitely turn yellow.

How to remove the jaundice of epoxy resin؟

If you want to produce a colored resin product, using a yellowed resin will not cause problems because the resin will combine with the paint pigments and its yellowing will be neutralized.

Do not put the resin in sunlight.

It is the use of UV-resistant resins that can increase the resistance of epoxy resin to yellowing.

Use anti-yellowing epoxy resin products.

If you have a resin product that has turned yellow due to sunlight, sand its surface.

Buy as much resin and hardener as used so that the raw materials of the past date are not stored in the workshop.

Important points when working with epoxy:

1_ Observing the mixing ratio of resin and hardener

The epoxy resin you bought must be used. Inside the consumption order, the maximum weight and height of the material for molding are mentioned. It is necessary to be careful to the maximum extent so that the resin does not overheat. In this case, ambient temperature and mixed weight are the most important parameters that will have a direct effect.

2_ Failure to overheat the resin:

Some friends preheat the resin, especially for thick resins, this is very common. Usually, we put the resin and hardener in hot water for five minutes, but if you are careful, it is thrown and the resin remains in hot water for more time (ten to fifteen minutes)، The drying process speeds up and heats up much faster, as a result, epoxy resin will boil.

3_ Paying attention to the ambient temperature where the resin and hardener are kept:

In the summer season, depending on the location of your workshop، The temperature inside the workshop may reach 30 degrees (or even more) and this will greatly increase the drying speed and actually decrease the geltime. The optimum workshop temperature is 23 – 25 °C. Also, the storage temperature of resin and hardener is very effective and should not be kept in a hot or cold place.

Real wonderful visual appeal on this internet site, I’d rate it 10 10.